Anti-Foam Control Solutions-- Expert Foam Control Solutions for Wastewater Therapy

Checking Out Various Kinds of Anti-Foam Control Solutions for Numerous Industries

The administration of foam in commercial procedures is a critical element that can influence both item top quality and operational effectiveness across different fields. Various industries, such as food and drink, pharmaceuticals, and wastewater therapy, face distinct difficulties related to foam formation, necessitating customized anti-foam options. From silicone-based agents to eco friendly choices, the option of suitable control steps varies considerably. Understanding these distinctions is essential for ensuring and maximizing procedures conformity with industry criteria. What ramifications do these differing options have for environmental factors to consider and operational techniques?

Comprehending Foam Formation

Foam formation is an intricate physical phenomenon that takes place when gas is entraped within a fluid, creating a stable structure of bubbles. This process is influenced by various aspects, including the residential or commercial properties of the liquid, the nature of the gas, and external problems such as temperature and pressure (Anti-Foam Control Solutions). The stability of foam is greatly figured out by the surface area stress of the viscosity and the fluid, as these homes determine just how easily bubbles can develop and persist

In numerous commercial applications, foam is an unwanted by-product that can prevent processes, decrease efficiency, and impact product quality. The formation of foam is usually exacerbated by frustration, blending, or chemical reactions, causing raised operational challenges. Recognizing the systems behind foam formation is important for establishing reliable control methods.

Kinds Of Anti-Foam Brokers

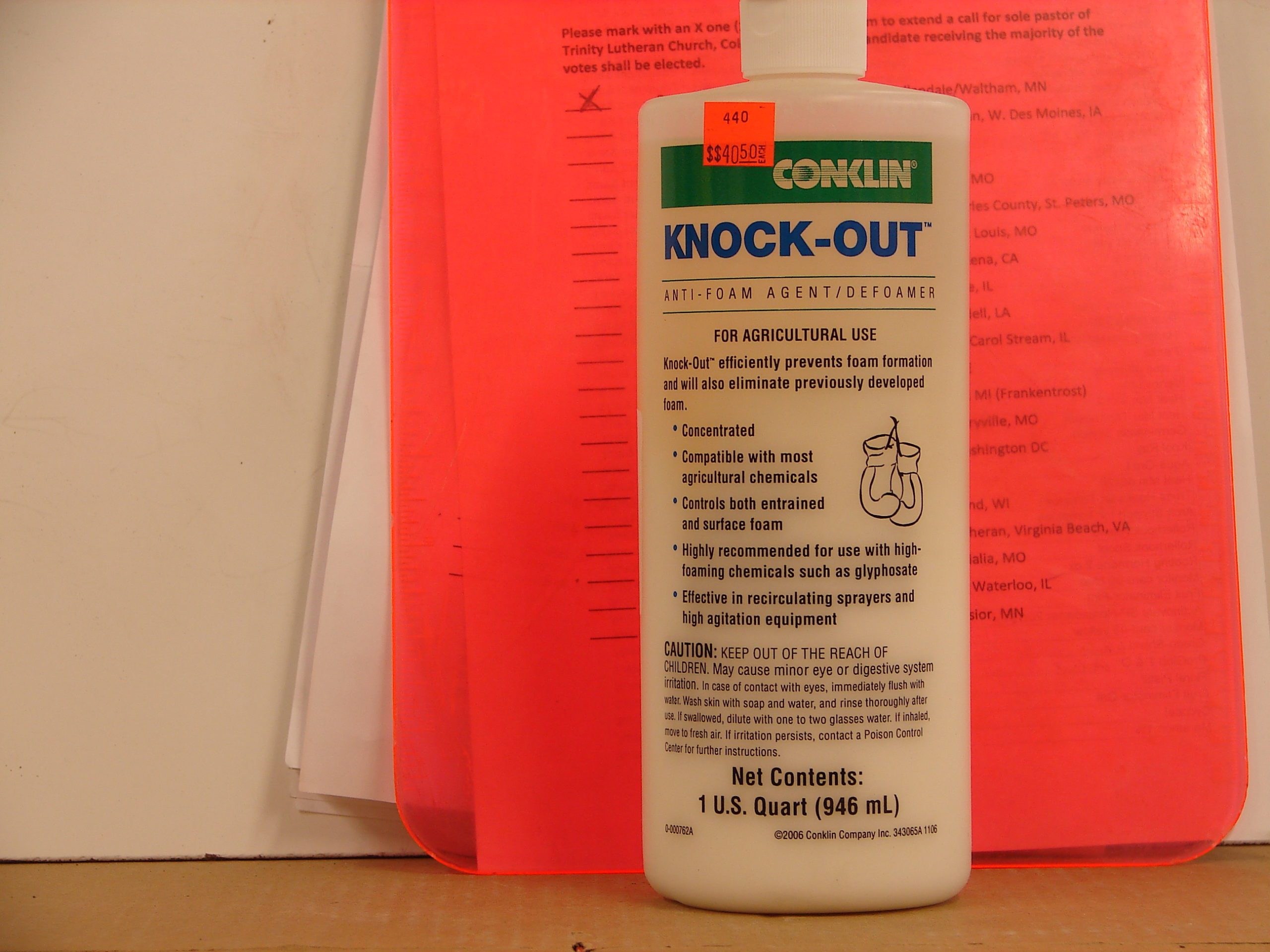

Numerous kinds of anti-foam agents are made use of across markets to battle the challenges positioned by foam formation. These agents can be extensively classified right into two main types: silicone-based and non-silicone-based anti-foam representatives.

Silicone-based anti-foam representatives are highly reliable as a result of their one-of-a-kind properties. They include polydimethylsiloxane (PDMS) and can dramatically reduce surface tension, permitting rapid foam collapse. Their stability at heats and in numerous pH environments makes them ideal for varied applications, consisting of production and chemical processing.

On the other hand, non-silicone-based anti-foam representatives consist of natural substances such as fats, esters, and waxes. These representatives frequently work as eco-friendly options to silicone-based products. They normally function by offering a physical obstacle that interrupts foam formation. Non-silicone representatives are commonly employed in applications where silicone contamination is a concern, such as in specific pharmaceutical processes.

Moreover, some anti-foam representatives integrate both silicone and non-silicone elements to enhance performance across certain conditions. Understanding the distinctive attributes and applications of these anti-foam agents is essential for choosing the appropriate solution for foam control obstacles in numerous commercial setups.

Applications in Food and Beverage

In the food and drink sector, efficient foam control is vital to ensuring product quality and procedure efficiency. Excessive foam can cause functional challenges, such as tools overflows, decreased handling capability, and disparities in product appearance. Numerous applications within this market, consisting of brewing, milk processing, and juice production, demand customized anti-foam services to attend to particular foaming issues.

For example, in developing, foam stability is vital for both the high quality of the beer and the effectiveness of the brewing process. Anti-foam agents are employed to minimize unwanted foam throughout fermentation and product packaging, ensuring a smoother process and preserving preferred tastes. In milk processing, the production of products like yogurt and cheese needs careful foam administration to prevent splilling and maintain structure.

In juice manufacturing, link foam can obstruct purification processes, impacting yield and clarity. Below, the application of suitable anti-foaming agents can enhance production rates and enhance product look - Anti-Foam Control Solutions. On the whole, selecting the right anti-foam control services tailored to the one-of-a-kind demands of each application is necessary for preserving top quality and efficiency in the food and beverage sector

Solutions for Pharmaceuticals

Effective administration of foam generation is vital in the pharmaceutical sector, where accuracy and pureness are extremely important. Foam can conflict with various procedures, including blending, purification, and sterilization, potentially jeopardizing item quality and visit homepage efficacy. As a result, the choice of suitable anti-foam options is important to keep functional effectiveness and regulative conformity.

Silicone-based anti-foam agents are commonly utilized because of their efficiency and compatibility with a range of pharmaceutical formulas. These representatives work by reducing surface area tension, thereby destabilizing the foam framework. Additionally, non-silicone choices, such as fatty acids and all-natural oils, are obtaining traction for their eco-friendliness and biodegradability, straightening with sector patterns towards sustainable techniques.

It is critical to take into consideration the details application when selecting an anti-foam option, as the formula should not negatively affect the active ingredients or the last product. Compatibility with cleansing and sterilization procedures is vital to ensure that the anti-foam representatives do not introduce contaminants. Constant monitoring and screening of foam control actions can enhance efficiency, making certain that pharmaceutical processes stay ideal and compliant with stringent industry requirements.

Wastewater Therapy Methods

As sectors progressively focus on sustainability, applying reliable wastewater therapy approaches has actually ended up being necessary for mitigating ecological effects. Wastewater therapy is a vital procedure that ensures the safe disposal or reuse of industrial byproducts, hence lessening air pollution and saving water resources.

One main strategy consists of using biological treatment methods, such as triggered sludge procedures, which utilize bacteria to break down organic contaminants. This approach is often complemented by sophisticated filtration and disinfection techniques, making certain the effluent satisfies governing standards.

Furthermore, chemical treatment choices, such as coagulation and flocculation, are utilized to remove put on hold solids and dissolved materials. The combination of anti-foam representatives is essential in this context, as foam can prevent treatment efficiency and make complex stages of information and separation.

In addition, membrane technologies, consisting of reverse osmosis, are obtaining traction due to their capacity to create top notch effluent suitable for reuse in numerous applications. Overall, a mix of these methods customized to details market demands can substantially enhance the efficiency of wastewater therapy, adding to a much more sustainable future.

Final Thought

Efficient foam control is vital across numerous industries to improve item top quality and process performance. The choice of ideal anti-foam agents, whether eco-friendly or silicone-based non-silicone alternatives, plays a vital function in addressing certain frothing obstacles encountered in food and beverage processing, pharmaceuticals, and wastewater therapy - Anti-Foam Control Solutions. Continued exploration of diverse anti-foam services page will facilitate enhanced functional end results while guaranteeing environmental compliance and resource healing, thereby adding to lasting practices within these markets

Various markets, such as food and drink, pharmaceuticals, and wastewater treatment, face unique difficulties connected to foam formation, necessitating customized anti-foam remedies. Various applications within this sector, consisting of brewing, dairy handling, and juice manufacturing, need tailored anti-foam services to deal with details lathering issues.

Anti-foam representatives are used to decrease unwanted foam during fermentation and product packaging, making certain a smoother operations and keeping preferred flavors. These agents function by decreasing surface tension, thus destabilizing the foam structure. The option of proper anti-foam representatives, whether silicone-based or eco-friendly non-silicone choices, plays a crucial duty in attending to particular foaming difficulties come across in food and drink processing, drugs, and wastewater therapy.